Home Product Range Carbon Tooling Pricing Gallery Contact

Sales and Technical - 021 289 1993

andrew@kiwitooling.co.nz

Distributors of Epoxy Polyurethane &

Carbon Fibre tooling board

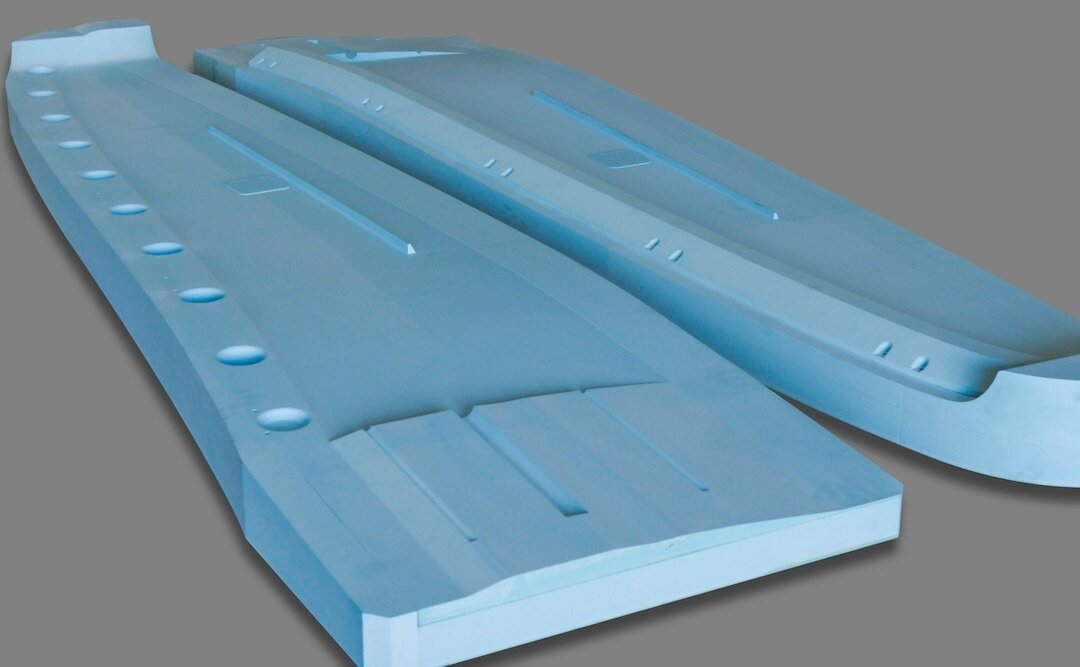

Distributors of Epoxy and Polyurethane and Carbon Fibre tooling board

CNC machining of tooling, plugs and patterns.

Tooling boards are consistent with no voids, uniform density and predictable processing characteristics. Small cell-sizes give excellent finished surface results straight from the tool, easily sealed and painted. With the demands of tighter tolerances and reliable dimensional stability, tooling boards out-perform traditional materials.

Tooling-boards are generally classified by density; encompassing a wide range of options, from medium-density foams to very dense, solid-plastic planks. This allows users to match materials to job requirements while controlling costs.

Faster CNC machine spindle speeds and material feed-rates are possible.

• Closed Cell Structure - Non absorbent

• Will not crack, rot or peel - Lasts up to 10 times longer than wood.

• Easily cut or machined with standard HSS cutting tools.

Polyurethane boards are temperature resistant to 60°C.

Epoxy boards can be used for pre-preg carbon fibre production that can be processed repeatedly at 125°C with very low thermal expansion, and good resistance to chemicals.

Carbon Fibre which is forged rather than laminated, easily machined with a CTE of 2.85. Temperature resistant to 200°C.

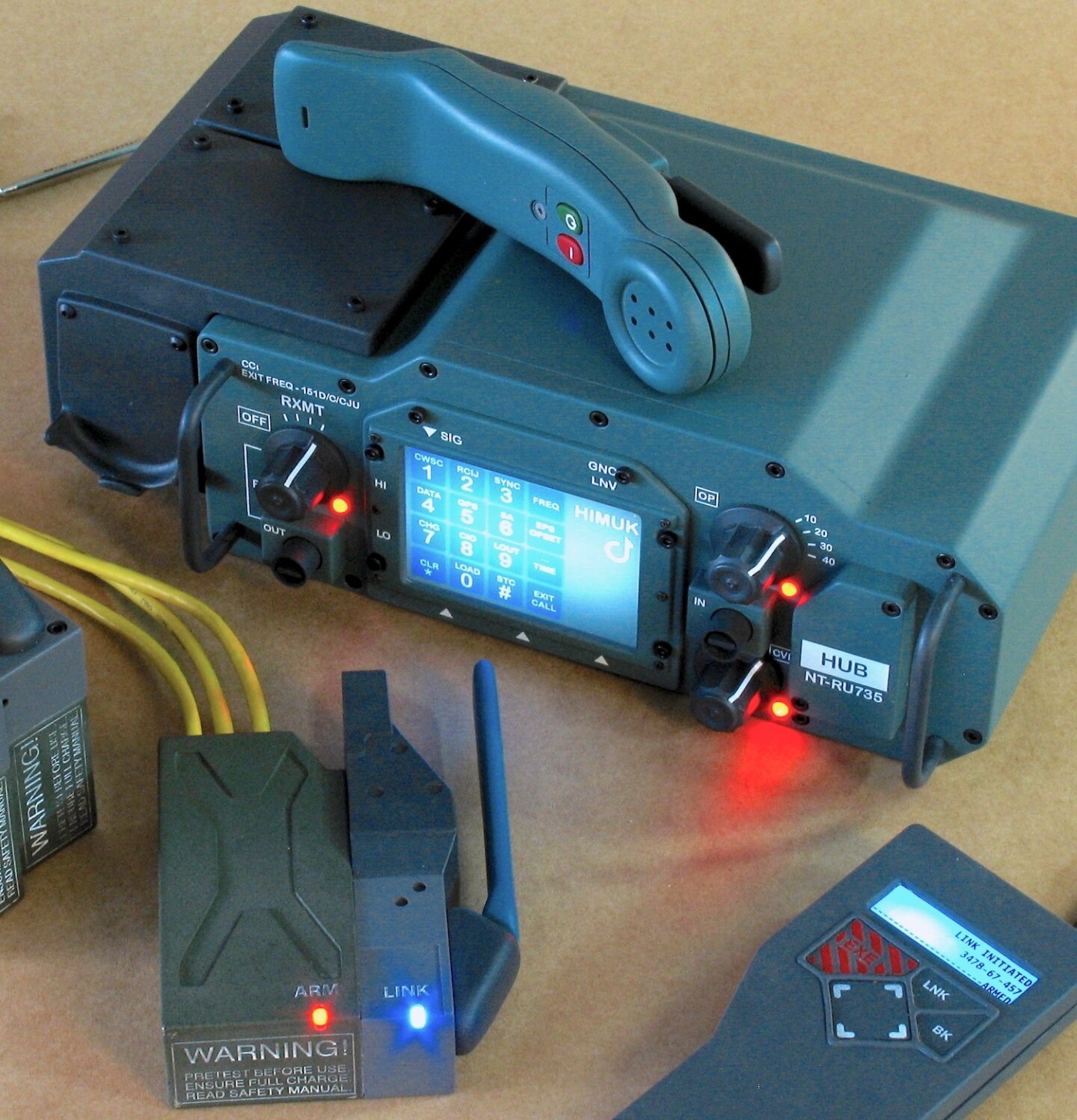

Common Applications: Lay up tools for Composites, Pattern Making, Design Models, Props and Models,

Prototype Machining, Vacuum Forming Tooling & Signage.